Automation Across Industries

Industrial Automation and the American Economy

Hello, I’m Ylli Bajraktari, CEO of the Special Competitive Studies Project. In this edition of 2-2-2, David Lin of SCSP’s Platforms Panel and Katie Stolarczyk of SCSP’s Economy Panel discuss the impact of industrial automation on the American economy, the implications for the workforce, and how the United States can harness the economic and social benefits of automation. This edition contains a number of gifs and images showing automation in action from a number of companies. Scroll down to watch.

Far too often, science fiction depicts an altogether bleak future for automation, one where the “machine revolution” or the “rise of robots” upends society and spells dire consequences for human progress. Such dystopian visions of a future featuring humans and ubiquitous autonomous systems, though certainly theatrical, are rather fanciful.

Today, we are surrounded by automation that has led to marked improvements in the human condition. In fact, automation can be as simple as a smart thermostat that adjusts the temperature in a house when no humans are present or autonomous trucks transporting products to a grocery store at the other end of the complexity spectrum. The trend towards increased automation will see these new technologies augmenting human workers in ways that boost labor productivity while making workplaces safer and more efficient. Automation will lead to advanced manufacturing that will dramatically increase our national economic competitiveness and will enable the United States to scale technology at levels not seen to date and out innovate our competitors.

There are many layers to the story when it comes to industrial automation’s impact on our nation’s workforce. The overwhelming majority of experts believe that increased industrial automation won’t translate into humans being replaced wholesale. Rather it will perform some human tasks, particularly the more mundane and dangerous, freeing the burden on humans to focus on more complex, valuable, and productive tasks. Many economists project that in the long run, automation technologies will create more jobs than they displace. Short-term worker displacement, however, should not be discounted. This has been true of nearly every impactful technological advance from the steam engine to the computer. There is invariably a period of disruption followed by adjustment, adaptation, and integration. That means both industry and government must ensure that workers negatively impacted by automation are given ample support and career opportunities.

We know that greater automation is coming to industrial production – America must prepare for that outcome both to take advantage of new opportunities and to ameliorate potential negative side effects. But given the all too often bleak terms in which automation is discussed, it is important to explain why industrial automation matters, explain what it looks like on the ground, and outline some initial frameworks under which the United States can address potential issues.

The Geopolitics of Industrial Automation

Both the United States and China are experiencing a slowing in productivity growth accompanied by increased workforce shortages. These unpleasant realities demand urgency in fully leveraging automation to ensure economic resilience and competitive advantage. Due to decades pursuing its one child policy, China’s population is shrinking, rather dramatically. That means it can no longer rely on a growing population to boost productivity and achieve economic targets, as it has for so long. For its economy to continue growing, Beijing must innovate to reduce its traditional reliance on population growth as a factor of production. With this in mind, Beijing’s industrial planners have set ambitious targets for investments in automation, dating as far back as 2006.

The United States also confronts workforce shortages, particularly in advanced manufacturing and strategically vital sectors such as shipbuilding, aircraft production, and microelectronics. Boosting domestic manufacturing, particularly for strategic industries, will require embracing automation and more robots on factory floors. If not pursued with urgency, America faces the very real risk of lagging behind the industrial powerhouse China in adopting automation. To this point, the International Federation of Robotics reported an all-time high for industrial robot installations globally in 2021, with China installing nearly eight times as many robots as the United States. It is essential that the United States government devise a framework and put in place the mechanisms to significantly accelerate the adoption and integration of industrial automation technologies to spur economic productivity, national competitiveness, and to bolster tech innovation across a wide variety of sectors.

Source: Wall Street Journal (2022).

Automation in Action

There is little question that automation is a game-changer for future techno-industrial competitiveness. To understand why this is the case and how automation is changing the future of work, it is essential to examine what automation looks like on the ground – or more to the point, on the factory floor. While the automotive industry is the dominant player in industrial automation today, such technologies are also emerging across a broader swath of industrial sectors, and innovative companies are building real world applications that automate labor-intensive, repetitive tasks, and fill labor shortfalls.

Disclaimer: The following real world examples are used to educate our readers on how emerging technologies already impact our economy. SCSP does not endorse any of the companies referenced in this newsletter or their products.

Agriculture

What comes to mind when somebody says agricultural production? Is it images of workers tending animals, driving massive combines across vast grainfields, or harvesting crops by hand? Or, is it autonomous tractors, machines able to sort between ripe and unripe tomatoes, and software that can sense and target weeds, determining the best herbicides to use against them?

Farmers have long turned to automation to compensate for worker shortages. For example, John Deere uses remote management and sensing technologies in its seeding equipment, harvesters, sprayers, and more. Still, labor shortfalls have significant implications for food security. In fact, for the first time in decades, the United States became a net importer of food. Greater automation could reverse this.

Depending on the type of crop, it can take a farmer 8-15 passes across a single field to grow a healthy crop. According to John Deere, their autonomous tractor is able to boost farmer productivity by twofold, enabling farmers to multitask and streamline efficiencies. Image from John Deere.

Logistics and Warehousing

Modern distribution warehouses no longer feature lines of people spending their days manually folding boxes and picking items off shelves. Instead, six-ton robot arms lift pallets too heavy for humans. Computer vision identifies and sorts items as they travel on conveyor belts and then drop into the right packages. On-time delivery is enabled by the speed and processing of automation. The global supply chain and the logistics sector that facilitates it, both stretched to its absolute limits by the COVID-19 pandemic, also face constraints due to the shortage of skilled workers. Fortunately, companies like Symbotic are developing robotic systems with sensing and machine learning capabilities to continuously improve warehousing and logistics operations that can lessen the global supply chain pressures.

Symbotic’s autonomous logistics system improves outbound efficiency up to nine times with 99.9 percent task accuracy, according to the firm’s website. Image from Symbotic.

Construction and Excavation

Construction and mining industry adoption of automation can pave the way for more rapid and cost efficient processes, while also creating safer working environments. Automation and AI can help workers conduct inspections and develop safer designs and execution plans at a new scale and magnitude. Automation in construction can range from planning and modeling software to autonomous excavators performing with high levels of precision. Between 1947 and 2010, construction productivity levels in the United States barely budged. With greater automation, workers can much more efficiently build roads, utility lines, and houses than human labor alone. Construction startup AIM, for example, designs and deploys software and hardware solutions to retrofit construction machines, such as excavators and bulldozers, so they can operate autonomously. These same technologies are of enormous merit to the mining sector.

AIM Intelligent Machine’s autonomous system installs on existing heavy equipment of any brand, age and size, and runs in dynamic environments in any weather without a human operator. Image from AIM Intelligent Machines.

Transportation

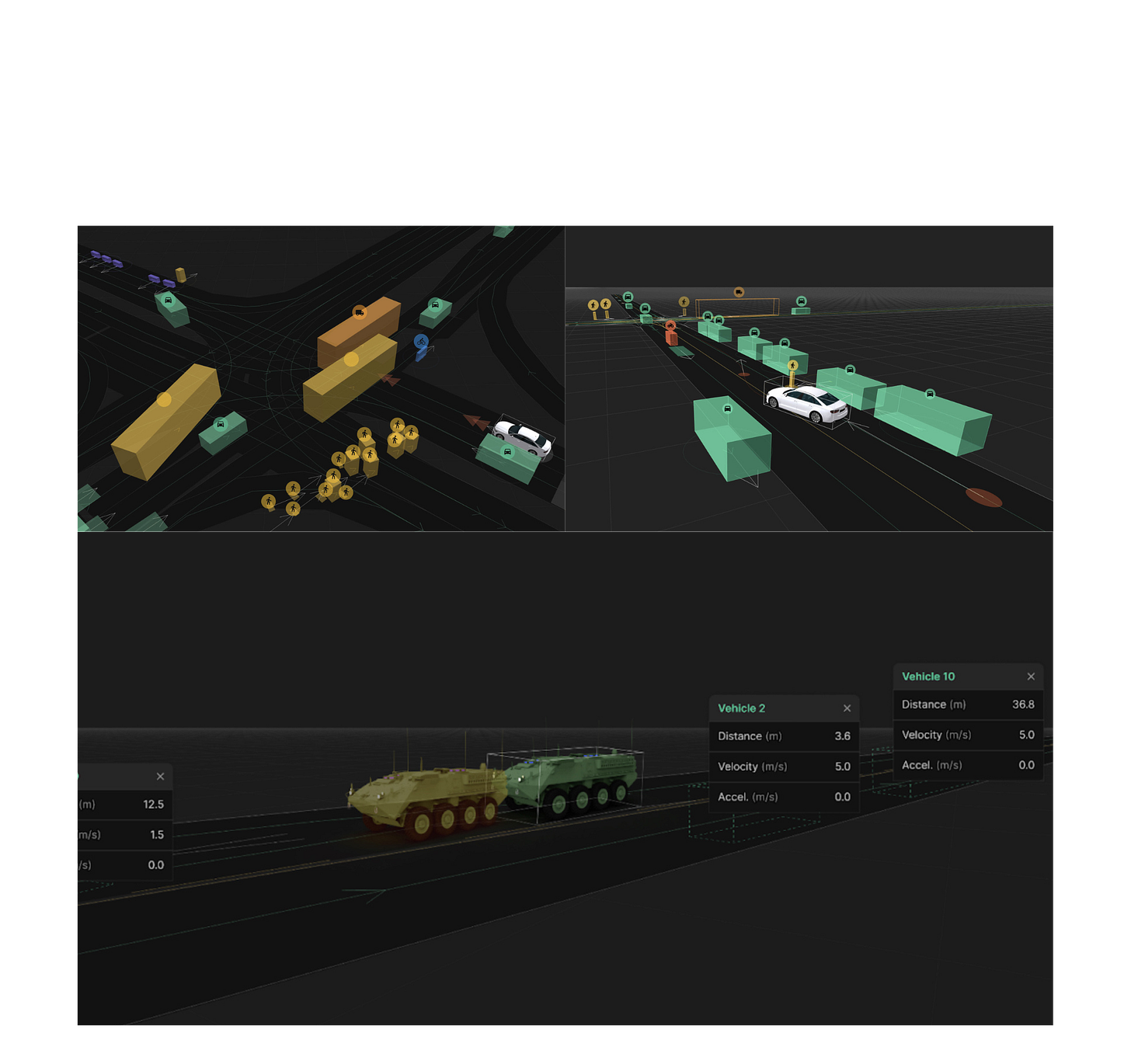

The prospect of self-driving vehicles is on the horizon. The hope is that one day, fleets of autonomous trucks carrying produce and packages will be able to drive through the night without taking breaks, arriving at their destinations faster. Self-driving cars will reduce the number of distracted drivers on the road, increasing safety and efficiency. While autonomous vehicle technology is still a work in progress, enormous progress has been made in recent years. Fully autonomous driving systems developed by companies such as Waymo and Cruise are in use today and many original equipment manufacturers (OEMs) in the automotive industry are integrating ever increasing autonomous capabilities into their vehicles. Companies such as Applied Intuition, support OEMs by developing software-based simulations to help validate OEM vehicle system precision, safety, and performance.

Applied Intuition’s Simian software reduces the need for time-consuming and dangerous on-the-road-testing through its fast scenario creation, simulations, and large-scale testing. Image from Applied Intuition.

Initial Policy Considerations

The brief examples we’ve highlighted demonstrate that industrial automation is changing the nature of work. It is transforming the way businesses are run and investments are made, while helping spur economic growth and national competitiveness by improving productivity. Yet barriers to greater adoption of industrial automation remain and will impede productivity growth if not addressed. In SCSP’s early survey of industrial automation, we identified several of these barriers that must be overcome to move the sector forward, particularly for small and medium enterprises (SMEs):

Barriers

Cost: Especially for small and medium enterprises (SMEs), the high cost to acquire, install, and maintain commercial automation systems is a key barrier. Some systems can cost millions of dollars including purchasing, training, licensing, and installation. SME reluctance is also driven by the uncertain return on investment.

Awareness of Federal Programs: SMEs, pressed by day-to-day challenges of their business operations, have limited bandwidth to learn about federal programs designed to help them and apply for support.

Lagging Policy Momentum: There have been a number of high-profile academic studies on automation in the United States, but implementation of their policy recommendations has lagged.

Recommendations

Tax Incentives: The United States could increase tax incentives for companies to purchase advanced industrial equipment, particularly for SMEs. Larger companies have more resources to adopt automation, but if SMEs fall behind or go out of business, the manufacturing base becomes less diverse and resilient.

Public-Private Partnerships (PPPs): PPPs such as the Manufacturing Extensionship Partnership and Manufacturing USA are located across the nation and can help SMEs with risk mitigation, technology scouting, and talent development. The United States should ensure adequate funding for outreach across the nation.

Establish a Commission: The United States should establish a commission to convene public and private stakeholders and develop targeted, action-oriented recommendations that encourage innovation and minimize worker displacement. A congressionally-mandated Commission on Automation and the Future of Work could be established to build on the learnings of previous efforts, and provide a more direct line to policymakers and legislators.

Ultimately, automation is essential to boosting productivity, performing tasks more safely and efficiently, and bringing manufacturing back to American shores. It will also have a geopolitical impact as countries race to shore up their techno-industrial base, and produce technologies more efficiently and at lower cost. These recommendations could help set the United States on a path toward harnessing automation to unleash economic and social benefits, while simultaneously taking steps to mitigate immediate impacts to workers, as the technology continues to evolve.